20 YEARS EXPERIENCE

There are more than 30 products to choose from

to meet your every need.

Products Description

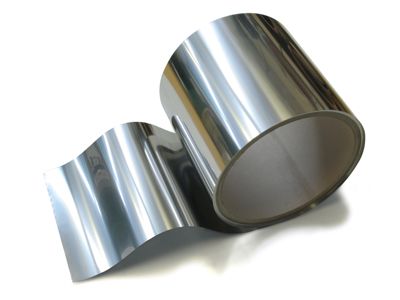

# Power Industry Stainless Steel Strip

## Product Overview

Welcome to our premium selection of Power Industry Stainless Steel Strip. Designed for the most demanding applications in power generation and transmission, our stainless steel strips are engineered to withstand extreme conditions while maintaining optimal performance. Whether you're looking for corrosion-resistant materials or high-temperature resistance, our products offer unparalleled reliability and durability.

## Product Features

### High Corrosion Resistance

Our stainless steel strips are made from high-quality alloys that provide exceptional resistance against corrosion, ensuring long-lasting performance even in harsh environments.

### Excellent Mechanical Properties

Engineered with precision, these strips exhibit superior tensile strength and yield strength, making them ideal for critical components in power plants.

### Temperature Resistance

Our stainless steel strips can operate efficiently at both extremely low and high temperatures, making them suitable for a wide range of power industry applications.

### Precision Tolerances

Every strip is manufactured to tight tolerances, ensuring consistent quality and performance across all batches.

## Material Specifications

| **Material** | **Grade** | **Chemical Composition (%)** | **Hardness (HB)** |

|--------------|-----------|------------------------------|-------------------|

| Stainless Steel | 304 | C: ≤0.15, Si: ≤1.00, Mn: ≤2.00, P: ≤0.045, S: ≤0.030, Cr: 18.00-20.00, Ni: 8.00-10.50 | ≤200 |

| Stainless Steel | 316 | C: ≤0.08, Si: ≤1.00, Mn: ≤2.00, P: ≤0.045, S: ≤0.030, Cr: 16.00-18.00, Ni: 10.00-14.00, Mo: 2.00-3.00 | ≤200 |

## Dimensions and Specifications

| **Width (mm)** | **Thickness (mm)** | **Length (m)** |

|----------------|--------------------|----------------|

| 5 - 150 | 0.01 - 1.0 | 500 |

| 151 - 300 | 0.01 - 1.0 | 500 |

| 301 - 500 | 0.01 - 1.0 | 500 |

## Usage Scenarios

### Power Generation Plants

Our stainless steel strips are widely used in the construction of boilers, heat exchangers, and condensers in thermal power plants. They ensure reliable operation under high temperatures and pressures.

### Renewable Energy Systems

In solar and wind energy systems, our strips are utilized in the manufacturing of solar panels, wind turbine blades, and electrical connectors, providing durability and efficiency.

### Transmission and Distribution Networks

Stainless steel strips are essential components in transformers, switchgear, and other electrical equipment, ensuring safe and efficient power distribution.

## Company Strengths

### State-of-the-Art Manufacturing Facilities

Our advanced manufacturing facilities are equipped with the latest technology, ensuring precision and consistency in every product we produce.

### ISO 9001 Certification

We adhere to strict quality control standards, earning us ISO 9001 certification for our commitment to excellence in manufacturing and customer service.

### Extensive Global Network

With a presence in multiple countries, we offer unparalleled logistics support and local expertise to meet your specific needs.

## Customer Testimonials

> "The stainless steel strips from [Your Company Name] have been performing exceptionally well in our power generation projects. Their durability and reliability have saved us significant maintenance costs."

> — John Doe, Project Manager, PowerGen Corp.

> "We have been using [Your Company Name]'s products for years, and their stainless steel strips have consistently exceeded our expectations. Highly recommend!"

> — Jane Smith, Engineering Director, Green Energy Solutions

## Frequently Asked Questions

### Q: What is the difference between Grade 304 and Grade 316 stainless steel strips?

A: Grade 304 is the most common type of stainless steel, offering good corrosion resistance and mechanical properties. Grade 316, on the other hand, contains molybdenum, which provides better corrosion resistance, especially in chloride environments. This makes Grade 316 more suitable for applications requiring higher resistance to corrosion.

### Q: How do I choose the right thickness for my application?

A: The appropriate thickness depends on the specific requirements of your project. Factors such as load-bearing capacity, environmental conditions, and operational temperature should be considered. Our technical team can assist you in selecting the best option based on your application's demands.

### Q: Can I customize the dimensions of the stainless steel strips?

A: Absolutely! We offer customization services to meet your exact specifications. Please contact our sales team to discuss your requirements and receive a quote.

### Q: What is the lead time for delivery?

A: Standard lead times vary depending on the order volume and current production schedules. Typically, it ranges from 2 to 4 weeks. For urgent orders, we can expedite the process for an additional fee. Please consult with our sales team for a precise timeline.

### Q: Do you offer any warranties on your products?

A: Yes, we stand behind the quality of our products and offer a warranty period of 12 months from the date of purchase. Should any issues arise within this period, we will work closely with you to resolve them promptly.

---

Thank you for considering [Your Company Name] for your power industry stainless steel strip needs. We look forward to serving you and helping you achieve your project goals with our top-quality products and exceptional service.

COMPANY PROFILE

OMPANY PROFILE

More+OUR ADVANTAGE

QUALITY CERTIFICATES

QUALITY CERTIFICATES QUALITY CERTIFICATES

QUALITY CERTIFICATES QUALITY CERTIFICATES

QUALITY CERTIFICATES OEM/ODM SUPPORT

OEM/ODM SUPPORT QUALITY CERTIFICATES

QUALITY CERTIFICATES 18 YEARS EXPORT

18 YEARS EXPORTPACKAGING LOGISTICS

Truck

Truck Sea Freight

Sea Freight Ari Freight

Ari Freight

Hot Tags: