20 YEARS EXPERIENCE

There are more than 30 products to choose from

to meet your every need.

Products Description

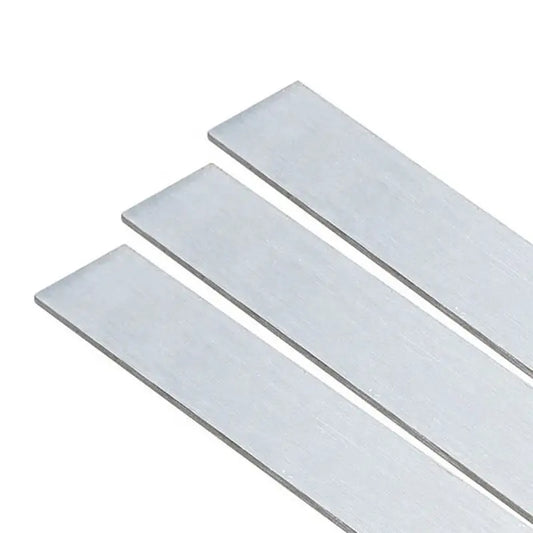

In today's world, stainless steel flat bars play a crucial role in various industries. These bars are made from high-quality materials that ensure durability, strength, and resistance to corrosion. In this article, we will explore the processing technology behind these bars, including their manufacturing process, specifications, size, and usage scenarios.

Product Description

Stainless steel flat bars are fabricated using advanced technologies such as cold rolling, heat treatment, and surface treatment. Cold rolling involves reducing the diameter of the bar through repeated deformation until the desired thickness is achieved. Heat treatment is used to improve the mechanical properties of the steel by heating and cooling it in specific temperatures. Surface treatment includes coating the bar with a protective layer to prevent rusting or corrosion.

Material

Stainless steel is a type of steels that contains at least 10% chromium and other elements to enhance its resistance to corrosion. This property makes stainless steel flat bars ideal for use in environments where corrosion is a concern, such as marine or industrial applications.

Specifications

The dimensions of the stainless steel flat bars vary depending on the application. Common sizes include 1/4", 3/8", 1/2", 3", 4", 5", and 8". However, custom sizes are also available upon request.

Size

Standard lengths range from 1/2" to 8", but custom lengths up to 36" can be produced upon request. Special orders are also welcome.

Usage Scenarios

Stainless steel flat bars are commonly used in a variety of industries, including automotive, construction, electrical engineering, and medical devices. They are used in applications requiring high strength, corrosion resistance, and durability.

Company Strength

At SD-Steel, we pride ourselves on our expertise in stainless steel processing technology. Our team of experienced engineers and technicians uses state-of-the-art equipment to produce high-quality stainless steel flat bars. We have a strong reputation for delivering on-time deliveries and meeting customer needs.

FAQs

Q What is the difference between hot rolled and cold rolled steel?

A Hot rolled steel has a higher yield strength and better plasticity compared to cold rolled steel.

Q How does surface treatment affect the performance of stainless steel flat bars?

A Surface treatment improves the resistance to corrosion and helps protect the steel from environmental damage.

Conclusion

Stainless steel flat bars offer a wide range of benefits, making them an essential component in many industries. Whether you need standard sizes or custom designs, SD-Steel is here to help. Contact us today to learn more about how we can assist your project.

COMPANY PROFILE

OMPANY PROFILE

More+OUR ADVANTAGE

QUALITY CERTIFICATES

QUALITY CERTIFICATES QUALITY CERTIFICATES

QUALITY CERTIFICATES QUALITY CERTIFICATES

QUALITY CERTIFICATES OEM/ODM SUPPORT

OEM/ODM SUPPORT QUALITY CERTIFICATES

QUALITY CERTIFICATES 18 YEARS EXPORT

18 YEARS EXPORTPACKAGING LOGISTICS

Truck

Truck Sea Freight

Sea Freight Ari Freight

Ari Freight

Hot Tags: